Bearing types

Here we give you an overview of the many different bearing types that we use in our wheels, castors and conveyor technology elements such as idlers.

Choosing the right bearing can be very important for the function, smooth running, rolling resistance, durability and service life of a wheel or roller.

We are also happy to fit special bearing types or specific bearing brands on request, just ask us.

Bearing types Wheels & castors

Plain bearing bore

A plain bearing bore is the cheapest type of wheel bearing and is generally used for light loads at slow speeds. Wheels with plain bearing bores are also often used in wet areas for stainless steel applications. Such wheels have a relatively higher rolling resistance compared to wheels with ball bearings.

Plain bearing bushes

Plain bearing bushes are generally used when a plain bearing bore is not sufficient, but ball bearings or roller bearings cannot be used. They are often used in wet areas for stainless steel applications or for heat-resistant wheels.

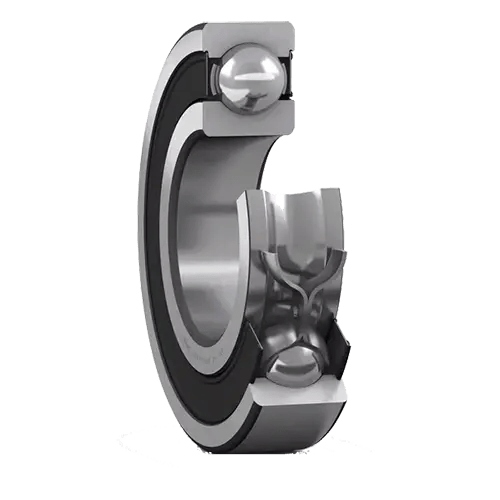

Deep groove ball bearing

Deep groove ball bearings with RS seals on both sides (sliding rubber seal) are our first choice when ball bearings are required.

They can only support radial forces (perpendicular to the axis).

The bearings are particularly well protected against dust and splash water and are lubricated maintenance-free.

Axial deep groove ball bearing

Axial deep groove ball bearings are special rolling bearings that support axial loads (i.e. loads running along the axis). It consists of an inner ring, an outer ring and balls that run between the two rings. In contrast to conventional radial deep groove ball bearings, which primarily support radial loads (i.e. loads that act perpendicular to the axis), an axial deep groove ball bearing is specially designed to transfer axial forces in one direction.

We use these bearings in the slewing ring of our welded heavy-duty castors in the LSO and LSON series as well as in the heavy-duty double swivel castors LDSO and LDSON.

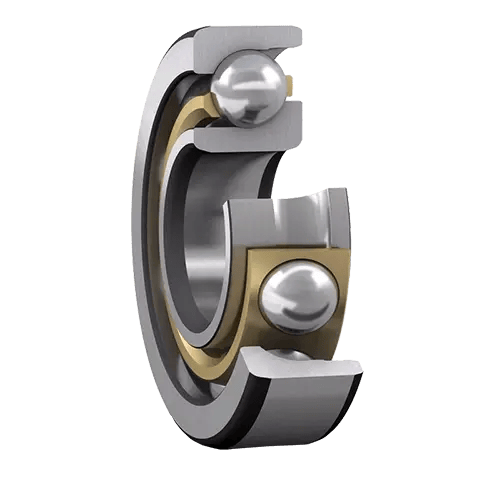

Angular contact ball bearing

The angular contact ball bearing is a rolling bearing that can support both radial and axial loads. It consists of an inner ring, an outer ring and balls that run in inclined raceways between the rings. These inclined raceways enable the bearing to support forces from different directions simultaneously, whereby the ability to support axial loads varies depending on the bearing design.

Self-aligning ball bearing

A self-aligning ball bearing is a rolling bearing designed to support radial loads and fluctuating misalignments. It consists of an inner ring, an outer ring with a spherical running surface and balls that run between these rings. The spherical running surface of the outer ring enables the bearing to compensate for small angular deviations (misalignments) between the shaft and housing without the balls jumping out of the raceway.

Roller bearing

A roller bearing is a type of rolling bearing in which the loads are transmitted by rollers (instead of balls). In contrast to ball bearings, roller bearings offer significantly lower rolling resistance, but they are open and therefore more sensitive to dust and dirt.

Tapered roller bearing

A tapered roller bearing is a two-part rolling bearing that uses tapered rollers as rolling elements. These bearings are designed in such a way that they can support both radial and axial loads in one direction. The tapered rollers and the raceways of the inner and outer rings are conical in shape, which concentrates the loads on a defined line. Due to their geometry, tapered roller bearings are particularly suitable for applications where high combined loads (radial and axial) occur, such as in the slewing ring of our welded heavy-duty rollers of the LSO and LSON series and in the heavy-duty double swivel castors LDSO and LDSON.

Cylindrical roller bearing

A cylindrical roller bearing is a rolling bearing that uses cylindrical rollers as rolling elements. It is primarily designed to support high radial loads, as the rollers have a large contact surface with the raceways. Compared to ball bearings, the cylindrical roller bearing offers a higher load carrying capacity and rigidity under radial loads. However, this design cannot support axial loads or can only support low axial loads, except in special designs that are constructed for this purpose. Cylindrical roller bearings are sometimes used in heavy-duty rollers

Spherical roller bearing

A spherical roller bearing is a rolling bearing consisting of two rows of barrel-shaped rollers that can align themselves. The raceway of the outer ring is spherically shaped, which enables angular misalignment compensation. This allows the bearing to compensate for misalignment and misalignment of the shaft in relation to the housing. Spherical roller bearings are suitable for high radial and moderate axial loads in both directions and are often used in applications with strong vibrations and oscillations, such as in conveyor systems, rolling mills and construction machinery.

You might also be interested in this ...

A well-rounded solution: our configurator

Rolling in the right direction: Our adviser

Find the ideal wheels and castors or conveyor technology components for your requirements and projects - with helpful tips concerning selection criteria, surfaces, load capacity an much more.

Get in touch with us

Do you have any questions or requests? You can send us an inquiry using our form and we will get back to you as soon as possible.

Or do you have any questions and need advice by the phone? Please give us a call.

When selecting wheels and castors, there are various bearing types that offer different properties depending on the application. The choice of the right bearing depends on a variety of factors such as load, operating environment, speed and mileage.

Important factors when selecting a bearing:

1. load: the bearing must be able to support the maximum expected loads, both static (when stationary) and dynamic (while moving).

2. speed: Higher speeds require bearings with low rolling resistance and high precision, such as deep groove ball bearings.

3. environmental conditions: Moisture, dirt, temperature and chemical influences can affect the service life of the bearing. Plain bearing bores or sealed stainless steel deep groove ball bearings offer better protection here.

4. maintenance requirements: While some bearing types (such as plain bearings) require little to no maintenance, others (such as roller bearings) require regular lubrication and cleaning.

5. cost: High-quality bearings with special properties are more expensive, but also offer better performance and service life.

6. life: Choosing the right bearing can extend the life of the entire application, especially under heavy loads and intensive use.

By carefully considering these factors, the right bearing can be selected for the application, maximizing the efficiency and longevity of the wheels and castors.

Here are the most common bearing types for Schwalb wheels and castors:

Plain bearing bore

- Description: A simple bearing with no moving parts, where the axle runs directly in the wheel body or the wheel rotates directly on the axle tube.

- Advantages: Cost-effective, low maintenance, limited resistance to dirt and moisture.

- Disadvantages: Higher rolling resistance, less suitable for high speeds and heavy loads, can squeak under certain circumstances.

- Area of application: Ideal for applications with low speeds, short distances and light to medium loads, e.g. light furniture or transport trolleys.

Roller bearing

- Description: A bearing with cylindrical rolling elements that run between two bearing rings. Also available in stainless steel.

- Advantages: Very smooth-running, low rolling resistance.

- Disadvantages: More sensitive to dirt and moisture, therefore susceptible to maintenance.

- Area of application: Ideal for applications where high ease of movement at moderate speeds is required.

Deep groove ball bearing

- Description: A bearing with spherical elements that run between two bearing rings. Also available in stainless steel.

- Advantages: Low rolling resistance, high load capacity, suitable for higher loads and speeds. With appropriate sealing, relatively maintenance-free (we very often use bearings with 2-RS seals)

- Disadvantages: As open bearings quite susceptible to contamination, can wear out more quickly under high loads. Slightly higher rolling resistance with 2 RS seals (rubbing rubber seal).

- Area of application: Suitable for applications with higher speeds and moderate to heavy loads, e.g. transportation equipment in industry, heavy-duty castors.