Conveyor technology - Carrying roller bearings

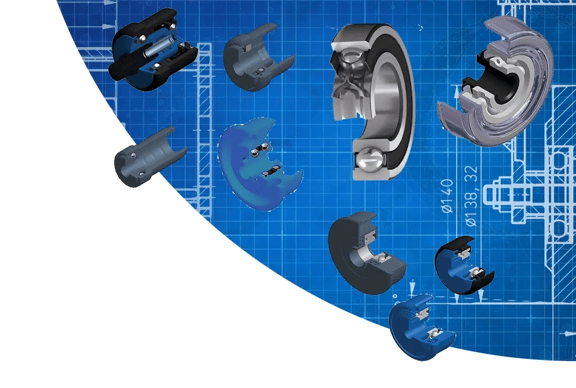

Here we give you an overview of the many different idler roller bearings that we use in our idlers.

The selection of the right bearing can be very decisive for the function, smooth running, rolling resistance, durability and service life of an idler.

We are also happy to fit special bearing types or specific bearing brands on request, just ask us.

Conveyor technology Support roller bearings

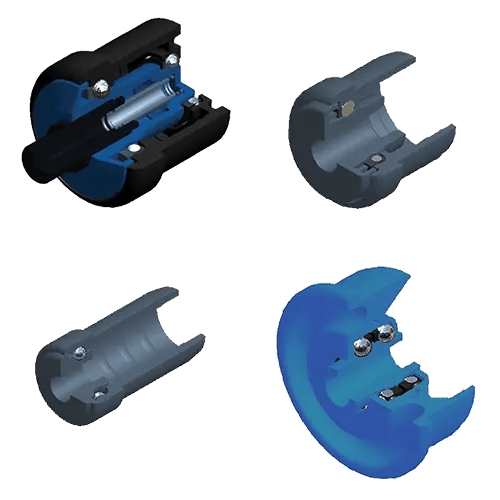

For smooth-running carrying rollers with PVC tube

Wheel body, hub and bearing cover made of plastic, with balls made of steel (TKL series) or stainless steel 1.4034 (TKLN and TSLKN series), pressed into the tube.

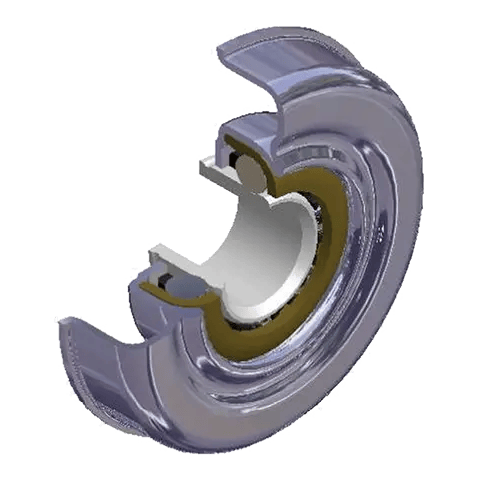

For medium-duty carrying rollers

Wheel body, hub and bearing cover made of plastic, with deep groove ball bearings and single labyrinth seal. Pressed into the tube.

Also available with stainless bearings for the stainless PVC and stainless steel support rollers TKMN and TSMN.

For smooth-running carrying rollers with steel tube TSL

For heavy-duty carrying rollers TSS

For heavy duty carrying rollers TSGK

For heavy duty carrying rollers TSGK

You might also be interested in this ...

A well-rounded solution: our configurator

Rolling in the right direction: Our adviser

Find the ideal wheels and castors or conveyor technology components for your requirements and projects - with helpful tips concerning selection criteria, surfaces, load capacity an much more.

Get in touch with us

Do you have any questions or requests? You can send us an inquiry using our form and we will get back to you as soon as possible.

Or do you have any questions and need advice by the phone? Please give us a call.

When selecting idlers, there are various bearing types that offer different properties depending on the application. Choosing the right bearing depends on a variety of factors such as load, operating environment, speed and mileage.

Important factors when selecting a bearing:

1. load: the bearing must be able to support the maximum expected loads, both static (when stationary) and dynamic (while moving).

2. speed: Higher speeds require smooth-running bearings with low rolling resistance, such as conical ball bearings or loose balls in a raceway.

3. environmental conditions: Moisture, dirt, temperature and chemical influences can affect the service life of the bearing. Sealed stainless steel deep groove ball bearings offer the best protection here.

4. maintenance requirements: While sealed 2Rs deep groove ball bearings require no maintenance, others (such as non-sealed low-friction bearings) may need to be renewed or replaced after some time.

5. cost: High-quality bearings with special properties are more expensive, but also offer better performance and service life.

6. life: Choosing the right bearing can extend the life of the entire application, especially under heavy loads and intensive use.

By carefully considering these factors, the right bearing can be selected for the application, maximizing the efficiency and longevity of the idlers.