Carrying Rollers with Sprocket Wheels

Manufacturing carrying rollers with various sprockets made of plastic (polyamide) or steel for your projects is a challenge we take on every day. They are used in a wide variety of powered conveyor systems for the fast and convenient movement of your transported goods. We are the right partner for your project. We will be pleased to take care of your requirements and advise you with a high level of expertise to ensure you will find the appropriate carrying rollers for your application.

Our Standard Sprockets

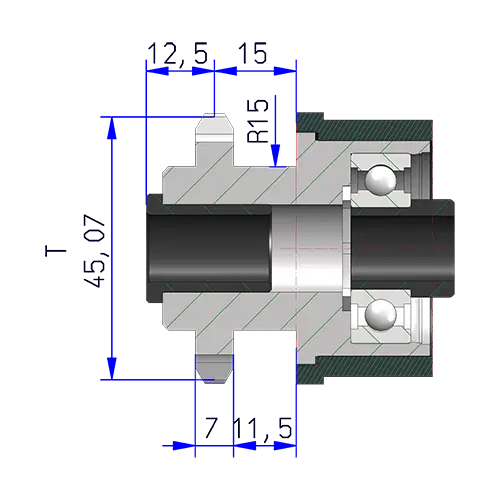

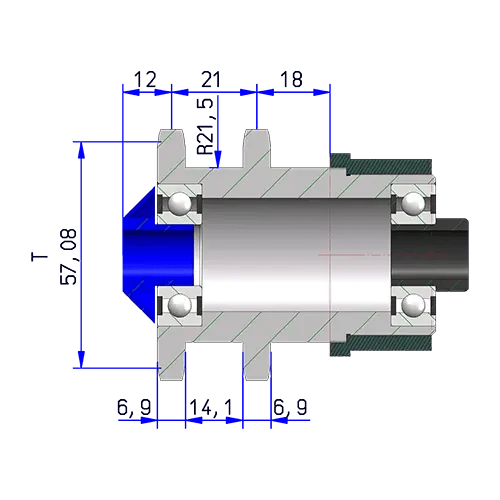

Steel sprocket

pressed

1/2 "x5/16" z11 (11 teeth)

Roller-Ø 50 mm

- with lantern gear toothing

- axle with internal thread

- external thread on request

Not suitable as fixed drive for stop-and-go

Available Roller Series:

- accumulation drive TSM1KS1/2z11S-IG

- fixed drive TSM1KS1/2z11F-IG

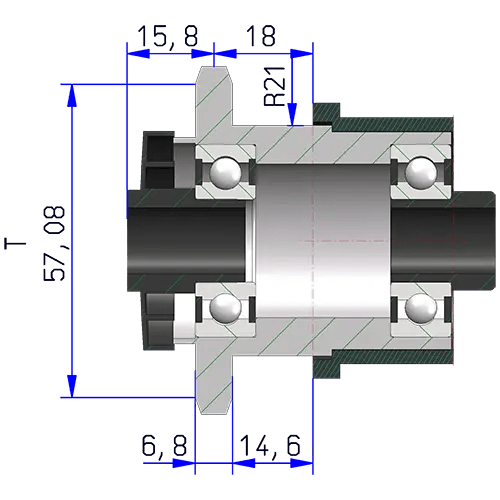

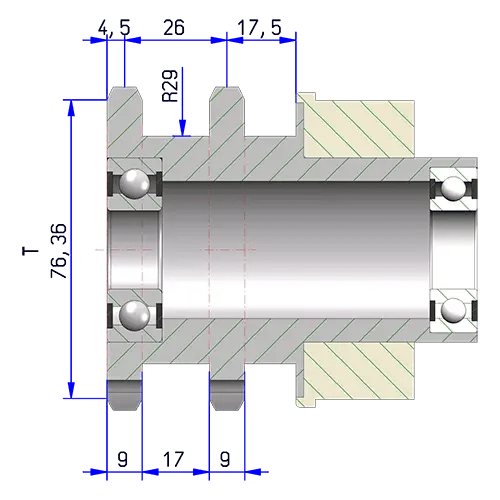

Steel Sprocket

pressed

1/2 "x5/16" z14 (14 teeth)

Roller-Ø 50 mm

- with lantern gear toothing

- axle with internal thread

- external thread on request

Not suitable as fixed drive for stop-and-go

Available Roller Series:

- accumulation drive TSM1KS1/2z14S-IG

- fixed drive TSM1KS1/2z14F-IG

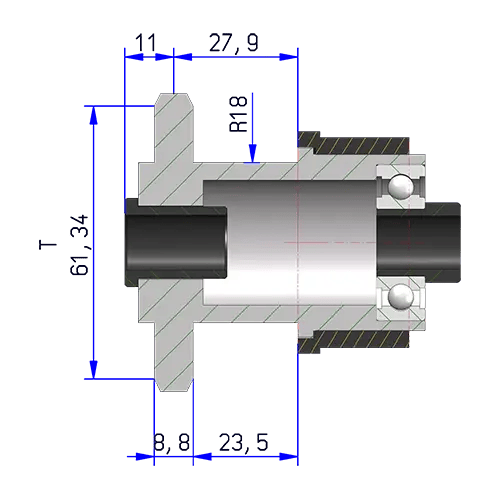

Steel Sprocket

pressed

5/8" z12 (12 teeth)

- with lantern gear toothing

- axle with internal thread

- external thread on request

Not suitable as fixed drive for stop-and-go

Available Roller Series:

- accumulation drive TSM1KS5/8z12S-IG

- fixed drive TSM1KS5/8z12F-IG

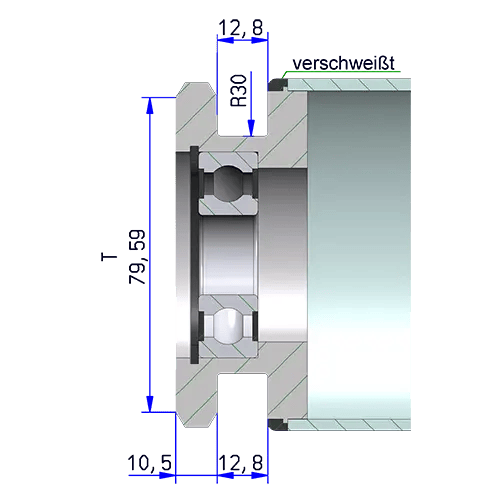

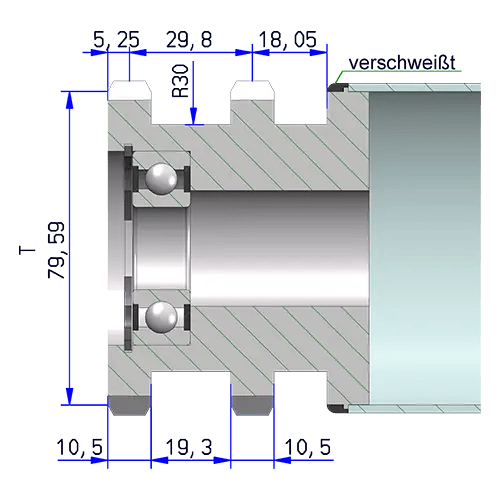

Steel Sprocket

welded

3/4 "x7/16" z13 (13 teeth)

Roller Ø 80 mm

- with lantern gear toothing

- welded to the tube

- axle with internal thread

- external thread on request

Available Roller Series:

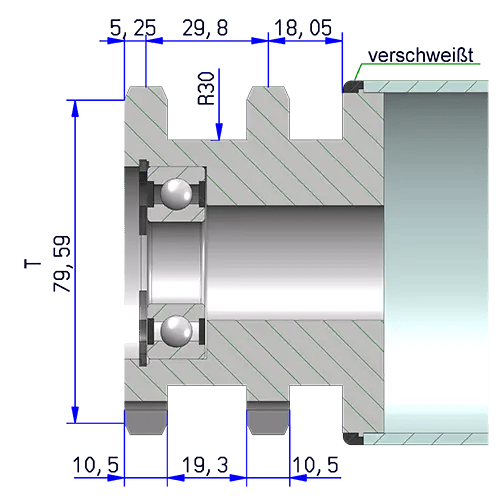

Steel Sprocket

welded

3/4 "x7/16" z13 (13 teeth)

Roller Ø 88.9 mm

- with lantern gear toothing

- welded to the tube

- axle with internal thread

- external thread on request

Available Roller Series:

Steel Double Sprocket

pressed

1/2 "x5/16" z14 (14 teeth)

Roller Ø 50 + 80 mm

- axle with internal thread

- external thread on request

Not suitable as fixed drive for stop-and-go

Available Roller Series:

- accumulation drive TSM2KS1/2z14S-IG

- fixed drive TSM2KS1/2z14F-IG

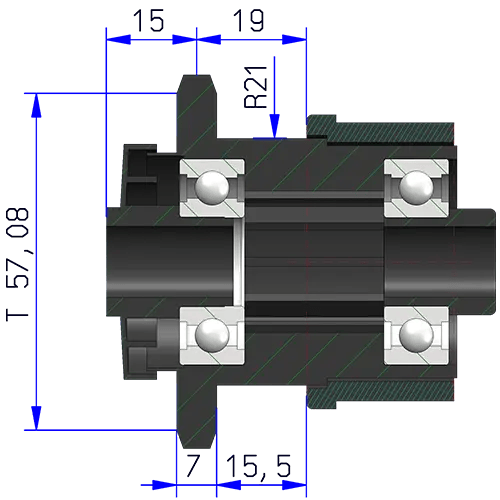

Steel Double Sprocket

pressed

5/8" z15 (15 teeth)

Roller Ø 80 mm

- axle with internal thread

- internal thread on request

Not suitable as fixed drive for stop-and-go

Available Roller Series:

- accumulation drive TSM2KS5/8z15S-IG

- fixed drive TSM2KS5/8z15F-IG

Steel Double Sprocket

welded

3/4 "x7/16" z13 (13 teeth)

Roller Ø 80 mm

- welded to the tube

- axle with internal thread

- external thread on request

Available for Roller Series:

Steel Double Sprocket

welded

3/4 "x7/16" z13 (13 teeth)

Roller Ø 88.9 mm

- welded to the tube

- axle with internal thread

- external thread on request

Available for Roller Series:

Plastic Sprocket

pressed

1/2 "x5/16" z11 (11 teeth)

Roller Ø 50 mm

- accumulation drive

- fixed drive

Not suitable as fixed drive for stop-and-go

Available Roller Series:

with Steel Tube

- accumulation drive TSM1KK1/2z11S-IG

- fixed drive TSM1KK1/2z11F-IG

with Stainless Steel Tube

- accumulation drive TSMN1KK1/2z11S-IGN

- fixed actuator TSMN1KK1/2z11F-IGN

with PVC Pipe

- accumulation drive TKM1KK1/2z11S-IG

- fixed drive TKM1KK1/2z11F-IG

with Stainless PVC Pipe

- accumulation drive TKMN1KK1/2z11S-IGN

- fixed actuator TKMN1KK1/2z11F-IGN

Plastic Sprocket

pressed

1/2 "x5/16" z14 (14 teeth)

Roller Ø 50 mm

- accumulation drive

- fixed drive

Not suitable as fixed drive for stop-and-go

Available Roller Series:

with Steel Tube

- accumulation drive TSM1KK1/2z14S-IG

- fixed drive TSM1KK1/2z14F-IG

with Stainless Steel Tube

- accumulation drive TSMN1KK1/2z14S-IGN

- fixed actuator TSMN1KK1/2z14F-IGN

with PVC Pipe

- Accumulation drive TKM1KK1/2z14S-IG

- Fixed drive TKM1KK1/2z14F-IG

with PVC Pipe Stainless Steel

- accumulation drive TKMN1KK1/2z14S-IGN

- fixed drive TKMN1KK1/2z14F-IGN

Plastic Double Sprocket

pressed

1/2 "x5/16" z14 (14 teeth)

Roller Ø 50 mm

- accumulation drive

- fixed drive

Not suitable as fixed drive for stop-and-go

Available Roller Series:

with Steel Tube

- accumulation drive TSM2KK1/2z14S-IG

- fixed drive TSM2KK1/2z14F-IG

with Stainless Steel Tube

- accumulation drive TSMN2KK1/2z14S-IGN

- fixed actuator TSMN2KK1/2z14F-IGN

with PVC Pipe

- accumulation drive TKM2KK1/2z14S-IG

- fixed drive TKM2KK1/2z14F-IG

with Stainless PVC Pipe

- accumulation drive TKMN2KK1/2z14S-IGN

- fixed drive TKMN2KK1/2z14F-IGN

Other Drive Elements.

Nothing found Maybe you need ...

You might also be interested in this ...

A Well-Rounded Solution: Our Configurator

Rolling in the right direction: Our Technical Guide

Find the ideal wheels and castors or conveyor technology components for your requirements and projects - with helpful tips concerning selection criteria, surfaces, load capacity an much more.

Get in touch with us

Do you have any questions or requests? You can send us an inquiry using our form and we will get back to you as soon as possible.

Or do you have any questions and need advice by phone? Please give us a call.

Carrying Rollers with Sprockets for your Conveyor Technology

Discover our extensive product portfolio in conveyor technology. Our roller conveyors and conveyor systems are made from high-quality materials and offer high stability and durability. We attach great importance to the quality of our components to ensure that our conveyor systems work reliably and efficiently. From conveyor rollers and idlers to ball transfer units and supports, we offer a wide range of components that can be individually combined in order to find the optimal material handling solutions.

To ensure the effficient transportation of your goods, it is important to select the most suitable conveyor rollers for your specific application. We provide an extensive selection of idlers with different tube diameters, bearing and axle types. Additionally, you can choose from a range of roller materials (steel, plastic, Vulkollan®) to meet your specific requirements. Stainless steel options are also available.

Where are Carrying Rollers/Conveyor Belt Rollers used?

How do I choose the right Carrying Roller/Conveyor Belt Roller?

By following the steps below, you can select the idlers that most effectively meet the needs of your conveyor system and its specific requirements.

- Load requirements:

Take into account the weight of the conveyor belt and the conveyed goods that must be supported by the idlers. Determine the maximum load to ensure that the carrying rollers are strong enough. - Speed of the conveyor belt:

The carrying rollers must be appropriately sized based on the conveyor belt's operational speed to ensure seamless movement. - Inclination angle:

If the conveyor belt is inclined, the carrying rollers must be able to support the weight of the conveyor belt and the conveyed goods even under this condition. Check the specific requirements for the inclination of your conveyor belt. - Environmental factors:

Consider environmental factors such as temperature, humidity and chemical resistance. Depending on the environment, special materials or coatings may be required for the carrying rollers to ensure optimal performance and longevity. - Specific application conditions:

Consider the specific application conditions of your conveyor system. This may include, for example, special requirements for noise levels, abrasion resistance or the grip of the carrying rollers. - Contact experts:

To ensure the optimal selection of carrying rollers and idlers it is advisable to seek expert advice. Please contact us, the manufacturer, to receive support in selecting the right carrying rollers and idlers for your specific application.

What are the Advantages of our Carrying Rollers

| Advantage | Description |

|---|---|

| Individual customization | We customize the carrying roller according to your specific requirements and dimensions. You have the option of adapting the tube diameter, bearing and axle type and other parameters according to your needs. |

| Technical expertise | We have extensive know-how and technical expertise in the production of carrying rollers and idlers. You can count on our experience to ensure that the carrying roller meets exactly your requirements and offers optimum performance. |

| Quality control | Please be assured that the carrying rollers are manufactured to high quality standards. We monitor the materials, manufacturing processes and final inspection to ensure that the roller meets the required quality standards. |

| Short delivery times | As a rule, delivery times are short. We can respond quickly to your individual requirements and you will receive the customized roller or idler immediately. |

| Customer support | Direct contact with us, the manufacture,r enables you to receive personal support. You can ask questions and receive technical advice and assistance on selecting the appropriate carrying roller for your application. |

By purchasing directly from us, the manufacturer, you receive a custom-made carrying roller that meets your specific requirements and offers you optimum performance. You benefit from technical expertise, quality control, short delivery times and direct customer support.