FAQ - Technology overview

Our technical guide aims to provide you with as much helpful information as possible and help you choose the right roller or wheel. The following is available here.

General

Wheel flattening due to standstill

A flat tire is a deformed tire caused by standing still and has a major influence on the starting and rolling resistance.

The tires on the side under constant load are deformed and no longer run true.

The closer the load on a wheel is to the maximum load limit, the greater the risk of the wheel flattening.

flattening of the wheel.

The starting and rolling resistance of wheels and castors

The starting resistance describes the resistance that a vehicle experiences when moving off from a standstill.

It is at its highest when the vehicle starts to accelerate and decreases as soon as it has reached a constant speed.

Rolling resistance (also known as rolling friction) is the force that is generated when a wheel or castor rolls and is directed in the opposite direction to the movement.

Please call us if you are unsure, we will be happy to advise you.

Find the right wheels and castors to suit the floor and surface:

Impact load on wheels and castors

When driving through potholes and over rails or sleepers etc., the wheels and castors sometimes receive considerable shocks or impacts that far exceed the normal load capacity and can therefore lead to destruction. If this cannot be avoided and in order to optimize the longevity of the wheels and castors, you should choose wheels or castors with elastic tread and the largest possible diameter and allow for fairly high load reserves. Our sprung castors often also offer an ideal solution for uneven road surfaces to absorb shocks and impacts.

Determining the load capacity of wheels and castors correctly

The following rule applies when determining the correct load capacity:

Tare weight + payload = total load.

In the case of 4-wheeled vehicles, the total load should always be divided by 3 as a rough estimate of the load capacity, as not all 4 wheels always carry the load equally (uneven floors, uneven load distribution, etc.). All specified load capacities apply to a maximum speed of 4 km/h on smooth, even and clean floors at a temperature of approx. 20°C. However, the load capacity is significantly reduced at increasingly higher speeds and/or other ambient temperatures. Special environmental influences may also have an effect on the load capacity.

Click here to calculate the correct load capacity in our load capacity calculator.

The most important environmental influences for Schwalb wheels and castors

Various environmental influences can be important factors for the correct selection of wheel materials for wheels or castors.

You can find the most important ones here.

Flexing/Fulling of wheels, Tyres and rollers

Flexing or fulling is the recurring deformation of elastic or plastic materials through mechanical processing such as kneading, pressing or pulling.

The flexing of a tire or wheel tread, for example made of rubber, refers to t he recurring deformation of the tire wall due to contact with the road surface under load. The elastic deformation of the tire or wheel tread leads to heating of the material due to internal friction.

The resulting heat corresponds to the so-called flexing work, the energy loss during power transmission and the main component of rolling resistance. The force required to flex the tire or wheel tread is the largest component of rolling resistance, works against the driving force of the vehicle and therefore increases the energy required to move the vehicle. Furthermore, the resulting heating of the tire can reduce its resistance to ageing and fatigue strength.

Want to find out more?

VULKOLLAN® is a registered trademark of the Covestro Group.

Vulkollan® is a high-performance elastomer based on Desmodur®15 and is manufactured in cast, foamed or pressed form. This material is used to manufacture technical molded parts, coatings for wheel cores and rollers as well as semi-finished products such as sheets, round rods, tubes, etc. for the highest demands. Vulkollan® is a registered trademark of the Covestro Group.

Conveyor technology

Idlers/Carrying rollers in many different designs

Idlers or carrying rollers are cylindrical components used in conveyors or conveyor systems to support conveyor belts or other moving parts. They help to distribute the load evenly and reduce friction, making the transportation of goods more efficient. Idlers are often used in conveyor belts, roller conveyors or similar applications to ensure stable and smooth movement.

Click on the button to get a good overview of our carrying rollers.

What is a drive shaft toothing?

Drive shaft toothing on sprockets in carrying rollers are a special type of toothing that enables direct power transmission between the drive chain and carrying rollers. It ensures a smooth drive, reduces slippage and improves running smoothness. This toothing is often used in conveyor technology applications where precision and efficiency are important.

Want to find such carrying rollers?

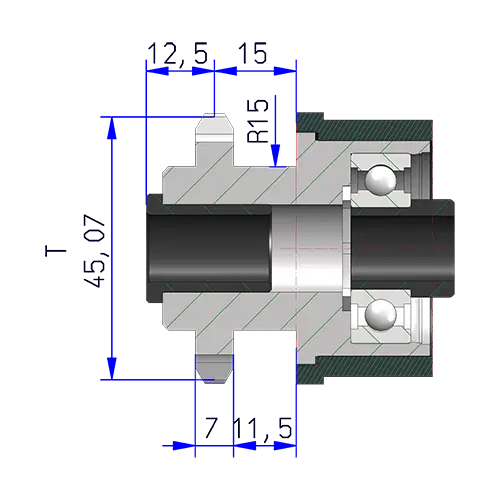

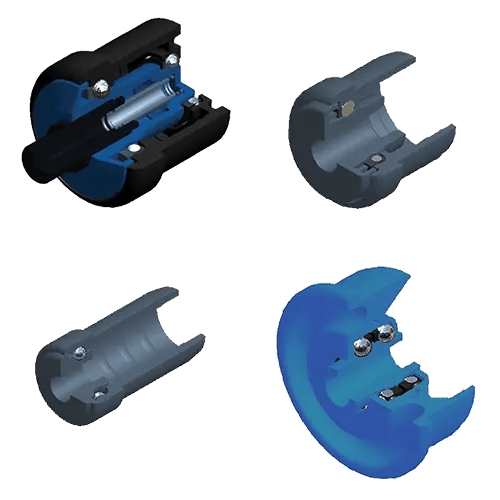

Overview of the different bearing types for carrying rollers from Schwalb

When selecting carrying rollers and other rollers for conveyor technology, there are various bearing types that offer different properties depending on the application. The choice of the right bearing depends on factors such as load, operating environment, speed and running performance.

When selecting wheels and castors, there are different types of bearings that offer different properties depending on the application. Choosing the right bearing depends on a variety of factors such as load, operating environment, speed and mileage.

Important factors when selecting a bearing:

1. load: the bearing must be able to support the maximum expected loads, both static (when stationary) and dynamic (while moving).

2. speed: Higher speeds require bearings with low rolling resistance and high precision, such as deep groove ball bearings.

3. environmental conditions: Moisture, dirt, temperature and chemical influences can affect the service life of the bearing. Plain bearing bores or sealed stainless steel deep groove ball bearings offer better protection here.

4. maintenance requirements: While some bearing types (such as plain bearings) require little to no maintenance, others (such as roller bearings) require regular lubrication and cleaning.

5. cost: High-quality bearings with special properties are more expensive, but also offer better performance and service life.

6. life: Choosing the right bearing can extend the life of the entire application, especially under heavy loads and intensive use.

By carefully considering these factors, the right bearing can be selected for the application, maximizing the efficiency and longevity of the wheels and castors.

Here you can find the most common bearing types for Schwalb wheels and castors.

Want to find out more?

Roller conveyors of the highest quality

Our roller conveyors offer the right solution for every requirement. Whether you need a small roller conveyor for light goods, a light roller conveyor for medium-sized loads or a heavy-duty roller conveyor for heavy-duty applications - we have the right product for your needs. Put your trust in our expertise and let us convince you of the quality and performance of our roller conveyors.

Important criteria for selection include the weight and size of your transported goods. The appropriate idlers, track width and roller pitch should also be selected.

Please contact us for individual advice and customized solutions for your conveyor technology.

Click on the link for further technical information on our roller conveyors, the profile, roller bearings, etc.

Wheels

Chemical resistance of the wheel materials polyurethane, polyamide and rubber

In our table you will find information on the chemical resistance to a variety of chemical substances and liquids for the wheels and wheel materials mentioned.

Click on the button to access the table.

Overview of the different bearing types for wheels and castors from Schwalb

When selecting wheels and castors, there are various bearing types that offer different properties depending on the application. The choice of the right bearing depends on factors such as load, operating environment, speed and mileage.

More information about our different bearing types

Overview of the different wheel materials

On a separate page, we give you an overview of the many different wheel materials in our product range.

Whether rubber, polyamide, polyurethane, cast iron, steel or a wide variety of heat-resistant wheels, we have the right tire or wheel material for you.

Rollers

Flexible foot protection for your safety

On the following page you can find out all about our flexible foot protection for our swivel castors, for your safety.

Want to find out more?

Directional locks for swivel castors from Schwalb

On the following page we give you an overview of the many different directional locks that we use in our swivel castors.

Want to find out more?

Overview of the most common arrangements of swivel castors and fixed castors

Due to the wide variety of requirements for the maneuverability of a transport device, there are different options for castor arrangements.

On the following page, we provide an overview of the most common castor arrangements with their respective advantages and disadvantages.

Want to find out more?

Direct contact with the design department?

Do you need individual advice and would like to speak directly to our design engineers?

Then send them an e-mail or call them directly.

Rolling in the right direction: Our guide

Find the ideal wheels and castors for your requirements - with helpful tips on selection criteria, surfaces and load-bearing capacity.

A well-rounded solution: our configurator