Conveyor technology technical information

Here we offer you detailed product specifications for our conveyor technology products such as idlers and roller conveyors.

This information is intended to help you make the right choice and is a supplement to the information on the individual series and products.

If you have any further questions, please call us or send us a message.

Carrying Rollers

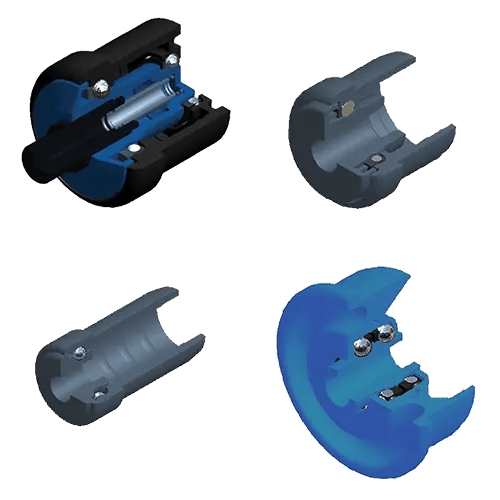

Axle designs of carrying rollers

Our carrying rollers can be supplied with the following axle versions (depending on the series, not every axle is available for all series)

- without axle (A)

- with smooth round steel axle (GA / GAN)

- with spring axle made of steel (FA / FAN)

- with grounded plastic stub axle (FAK / FAKN)

- with external thread (AG / AGN)

- with internal thread (IG / IGN)

- with width across flats (SW)

- with slip-on caps for width across flats (AKSW)

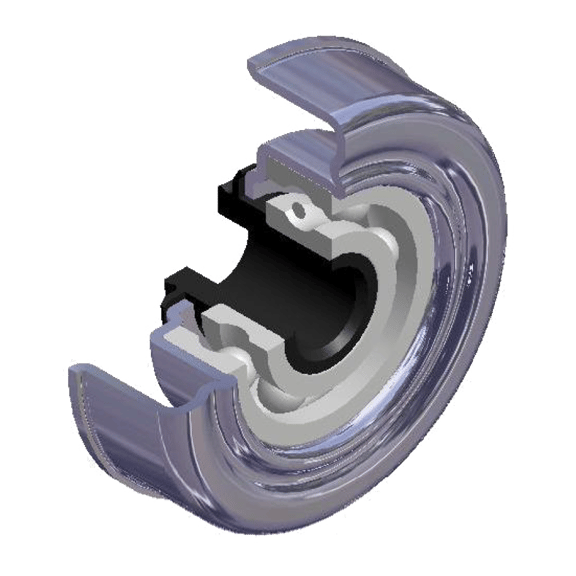

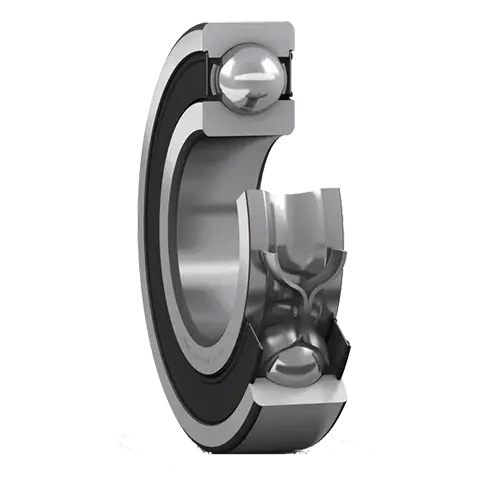

Bearing types of carrying rollers

Our idlers can be manufactured with different carrying rollerbearings.

- for smooth-running idlers

- for medium-duty idlers, sealed bearings

- for heavy-duty idlers

Click on the two buttons for more information.

Roller conveyors

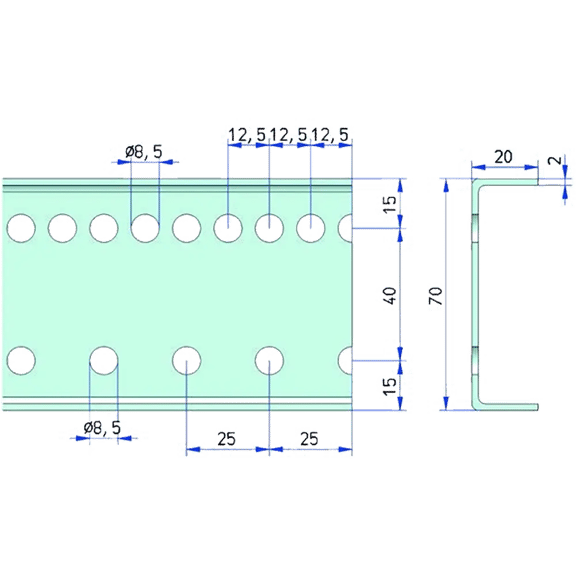

Various roller conveyor profiles

for small roller conveyors Ø 20 mm

We use this profile for our small roller conveyors in the KRB/TKL and KRB/TSL series for roller Ø 20 mm. The smallest pitch of 25 mm is possible here.

for small roller conveyors Ø 30 mm

We use this profile for our small roller conveyors in the KRB/TKL and KRB/TSL series for roller Ø 20 mm. The smallest pitch of 37.5 mm is possible here.

for light roller conveyors Ø 50 mm

We use this profile for our lightweight roller conveyors in the LRB/... series for roller Ø 50 mm. The smallest pitch of 62.5 mm is possible here.

As our roller conveyors are always made to order, returns and/or cancelations are not possible, even during the delivery period. Light roller conveyors are used for conveyed goods with low weights. The LRB/TSL series with steel rollers can be used for conveyed goods weighing up to approx. 30 kg/unit (guide value).

The selected support spacing, which should be a maximum of 2.0 m, must be taken into account. The center distance or roller pitch refers to the dimension from roller center to roller center and must always be selected so that your conveyed goods can rest on at least 3 rollers. For use in dry rooms at normal temperatures.

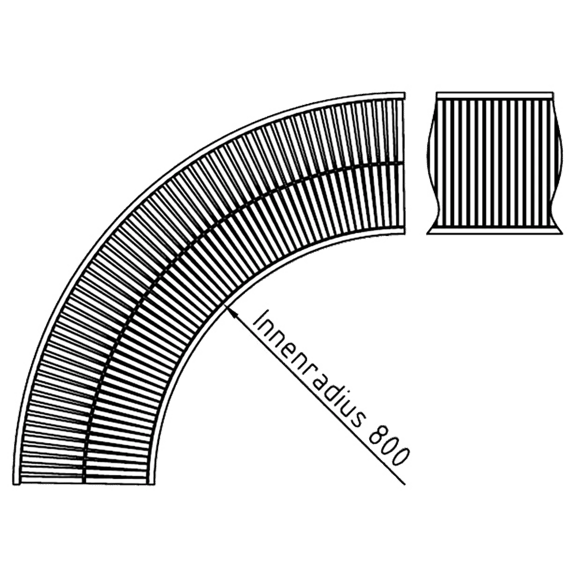

Curves: Inner radius 800 mm

Carrier rollers continuous or split several times depending on track width

Track width 100 - 300 mm = continuous, track width 400 mm = 2-split, track width 500 - 600 mm = 3-split.

A well-rounded solution: our configurator

Rolling in the right direction: Our adviser

Find the ideal wheels and castors or conveyor technology components for your requirements and projects - with helpful tips concerning selection criteria, surfaces, load capacity an much more.

Get in touch with us

Do you have any questions or requests? Send us an inquiry using our form and we will get back to you as soon as possible.

Or do you have questions and need advice over the phone? Then give us a call.